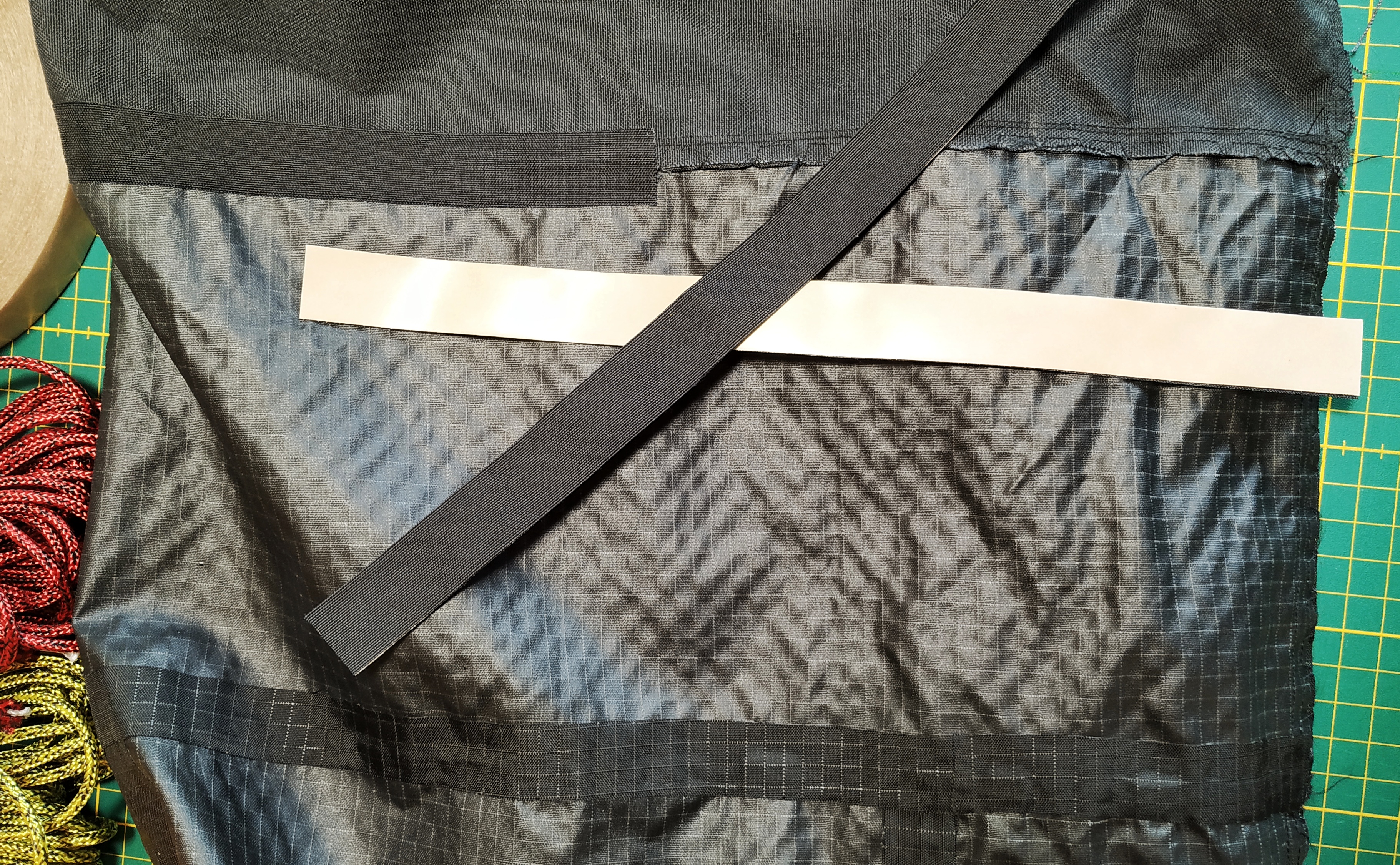

Let me share with you some afterthoughts on my first foray into seam-sealing. I did a bit of digging, and opted to use 3M 9485PC double sided transfer tape. Overall, it’s a great product to work with, but I think the fabric used here, (Dyneema®/Nylon Ripstop) is too heavy and does not bend well enough to really work as a the internal face of the seam sealing. If I was to do it again, I would probably go for DCF.

One interesting learning I made, is that on lightweight silicon-coated Nylon fabric (60g/m²), this tape did not stick at all! I wasted a good strip. I don’t have the reference anymore, but I would assume the Dyneema®/Nylon Ripstop fabric that really worked well was PU coated. Beware!

This experiment taught me one important thing: I will not seam-seal my pack except in very specific circumstances. It’s just too much of a hassle.

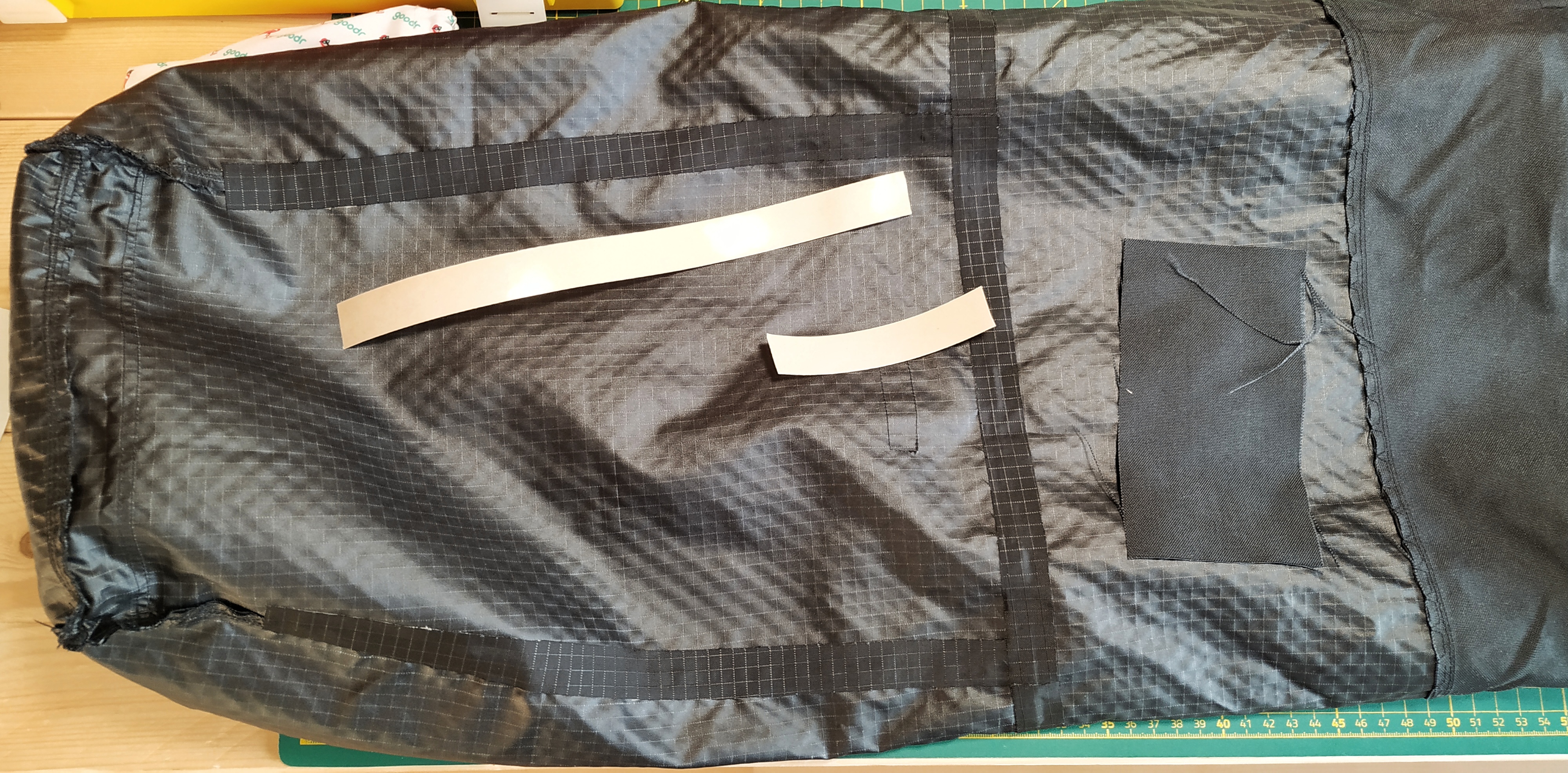

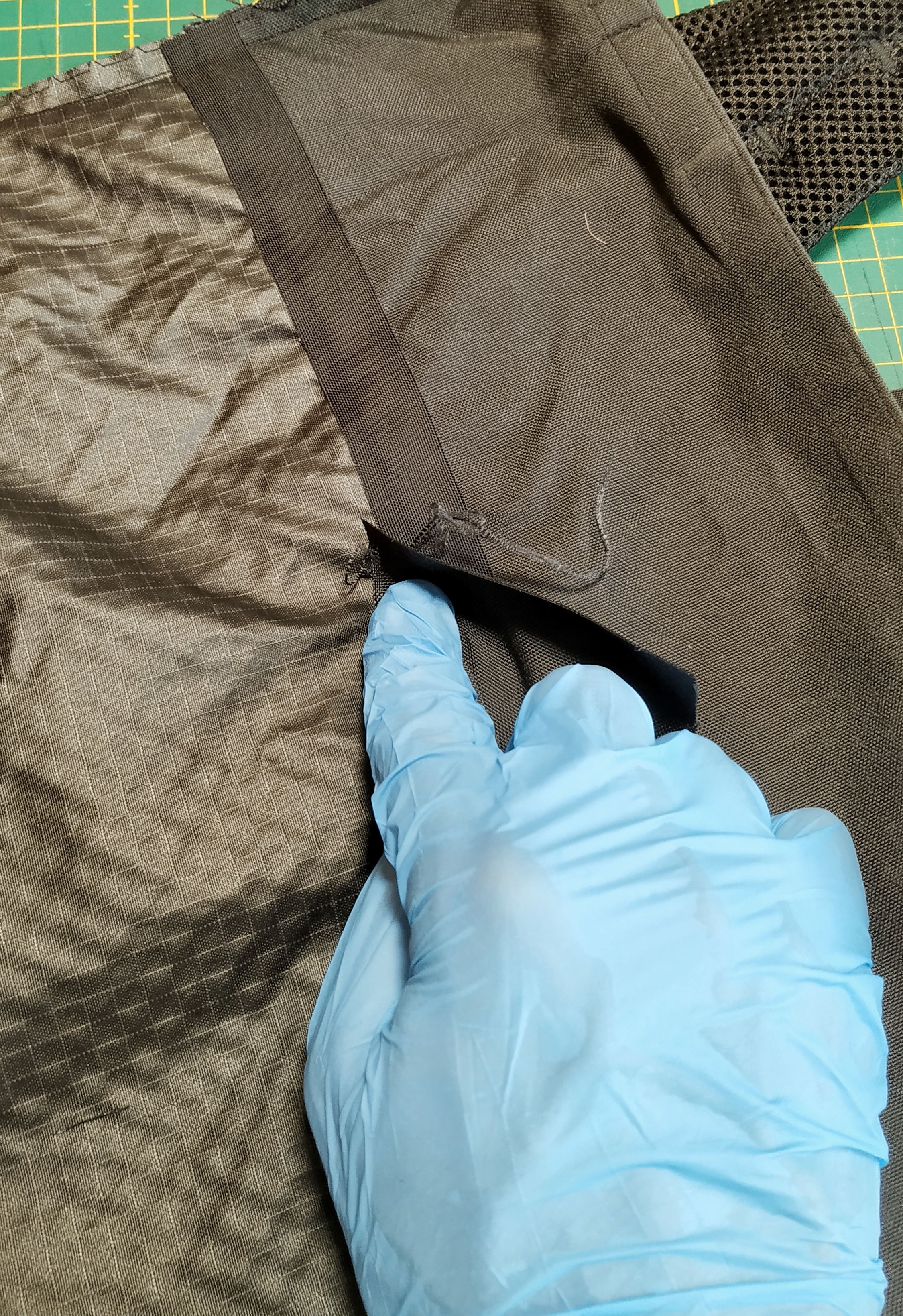

Here are a few pictures of the construction process behind building the Skinny pack. If you are wondering why I am wearing gloves in some of the pictures, it’s because I wasn’t sure how sticky the stuff is. I turned out to be utterly unnecessary, and I quickly removed them.