This one is for the Instagram community after I just hit 1000 followers. There is no small victory 💪 and these little steps matter to makers like myself. I don’t build bags nor do I document my work for money, I do it for the community that supports me. Now, what could I do to thank you all? I decided that I would make the ultimate pack.

After a lot of drawings, and a lot of thinking, and a lot of coffee to stay awake, I decided that this special pack would solve the single most annoying problem with ultralight packs. I mean, we’ve all been there, you have that one piece of gear that you know is inside your bag. You know you packed it, but you can’t ever take it out without emptying the entire bag, because this one puny piece of equipment always finds its way to the bottom of the pack. Well, I fixed this once of for all. I present to you… the Burrito pack!

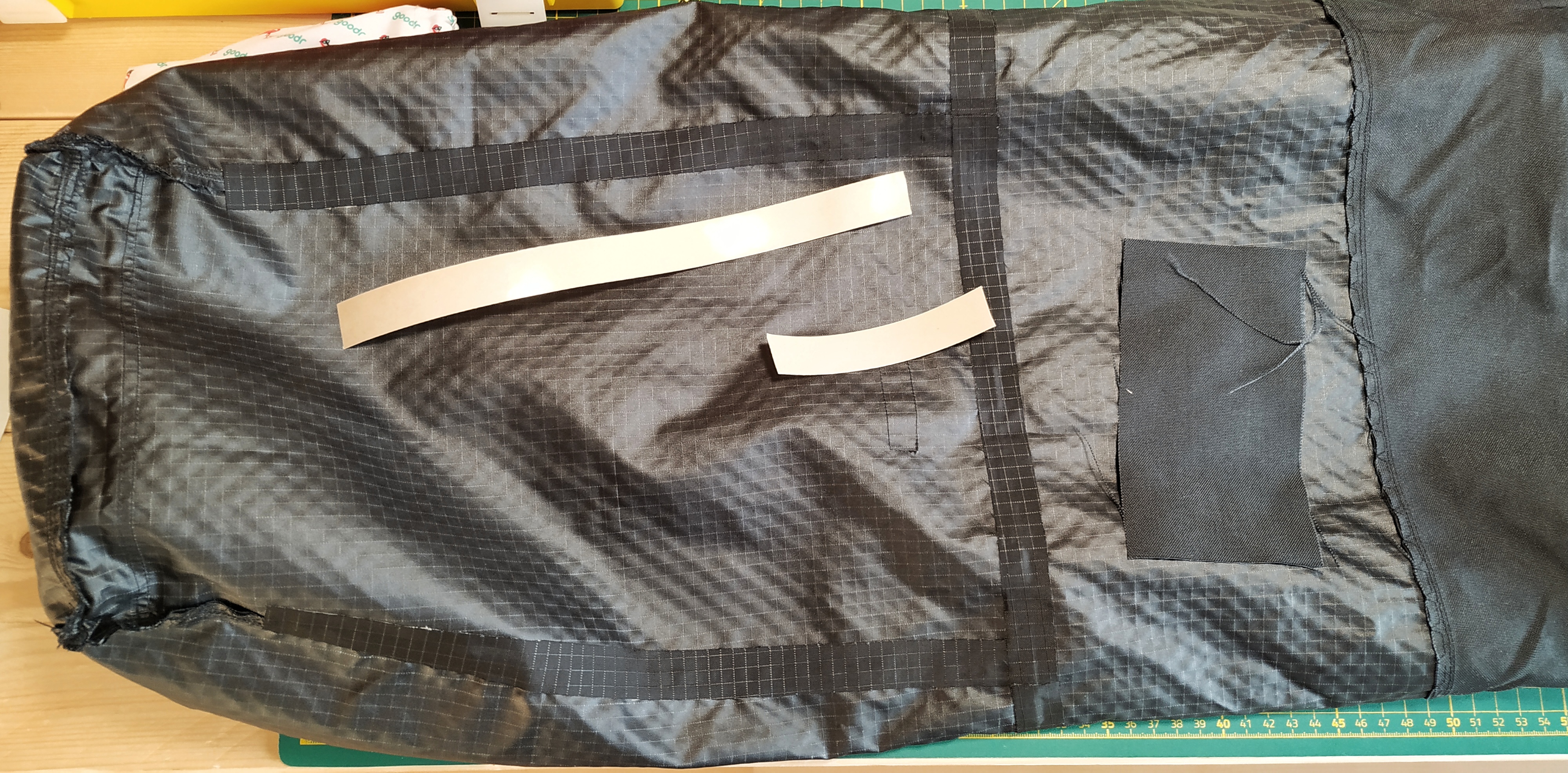

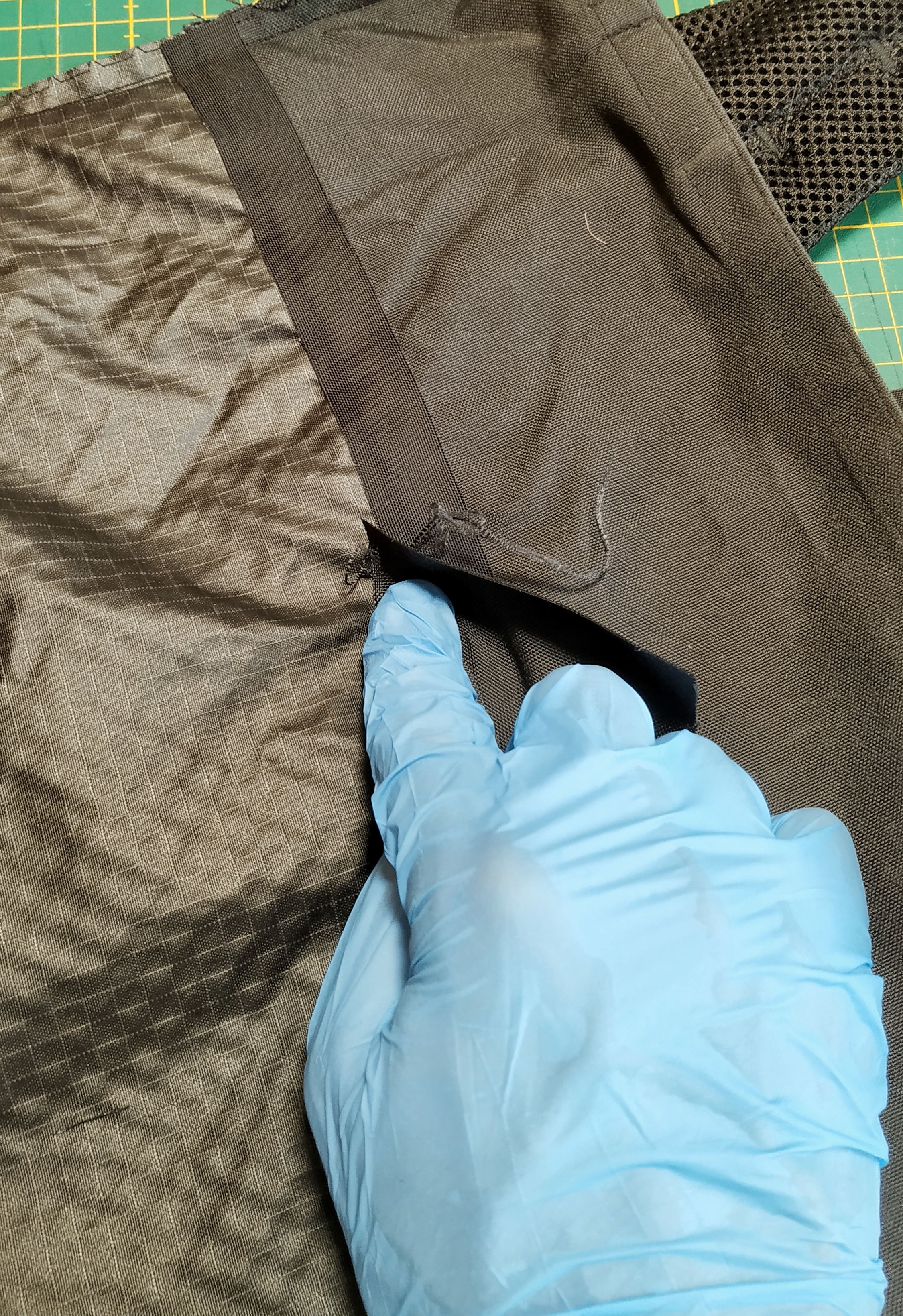

Bam! There you have it! That puny piece of gear no longer has a bottom to fall to! The Burrito pack opens from the top and bottom with not one but two roll… tops? No, sorry, with a roll-top and a roll-bottom . And since it’s a special build for a special occasion, I thought I’d etch that “1000” on its side.

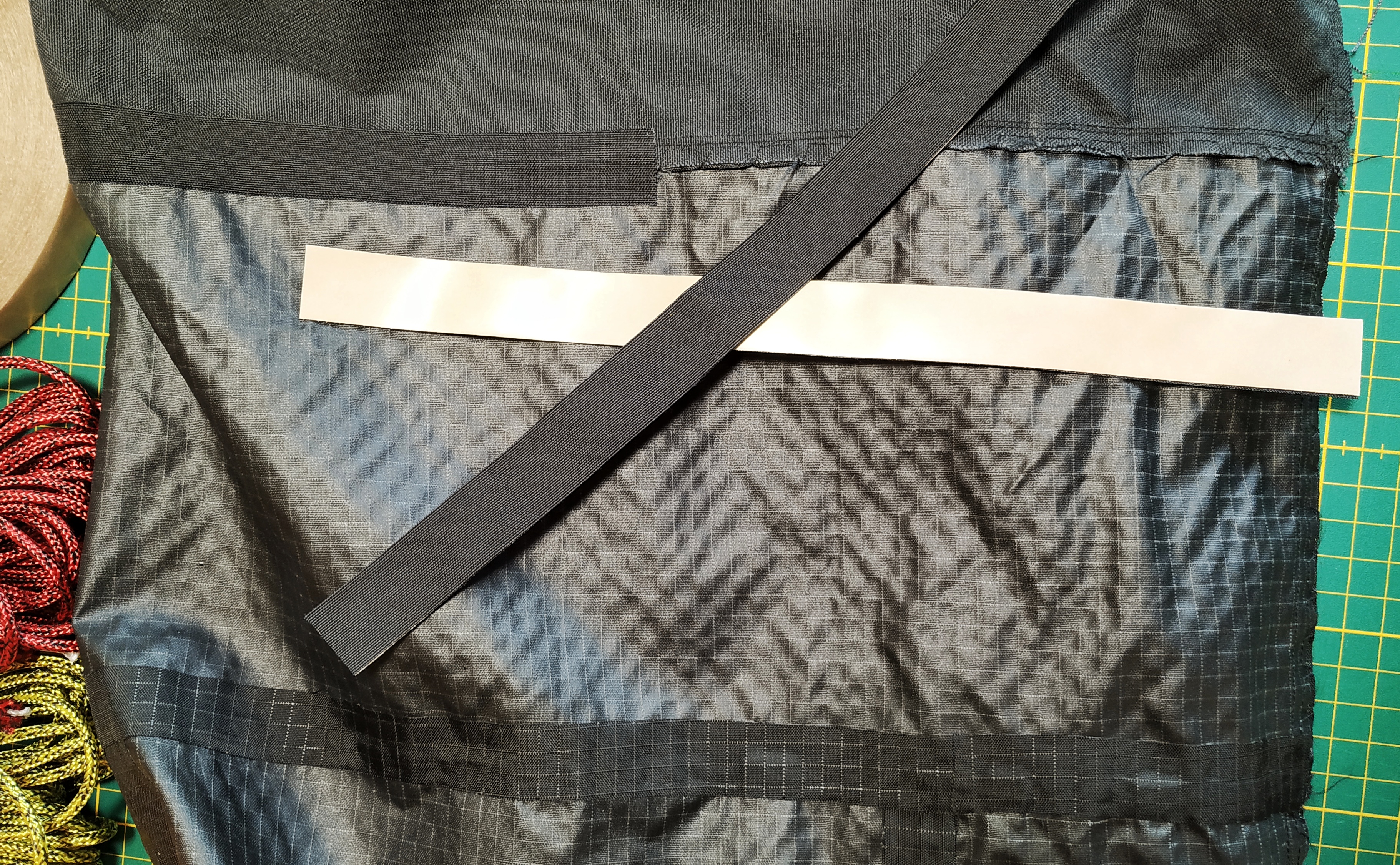

Roll-bottom forever baby. I can retire now. Oh, you’re still here? Ah you must be wondering what that gorgeous fabric is huh? I knew you would ask. I’ll give you a hint…

There won’t be any behind the scene for this pack, I need to keep this a secret.